Improving Crutches Tip

Team Members: Amos Sng, Zhi Ying, Edwin, Zaina and Yu Quan

Background:

Crutches are walking aids that is used to remove the stress from the leg of the patients that is supporting

the body weight. This helps to speed up the recovery process for those that is experience lower limb injuries. However,

most crutches available out in the market perform poorly on slippery surface. One of the main reason is due to the only available

backforce to counteract slipping is friction, which is dependent on friction coefficient between the tip and the surface. Other anti-slip

crutch tips are expensive, which does not make economical sense as most patients only use it for a short period of time.

Problem Statement:

How might we improve the tip of the crutch that reduces the chances of slipping on slippery surface for patients suffering from lower limb injury?

Our Solution:

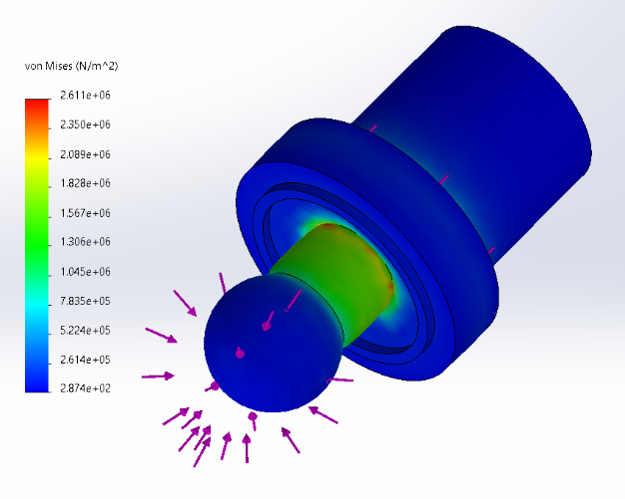

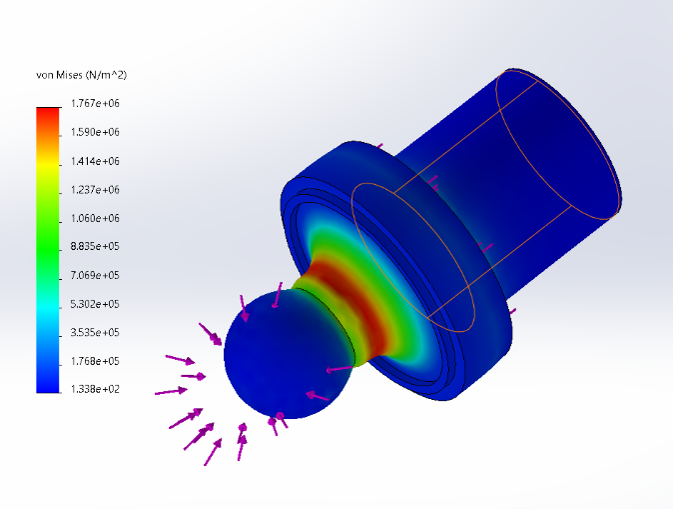

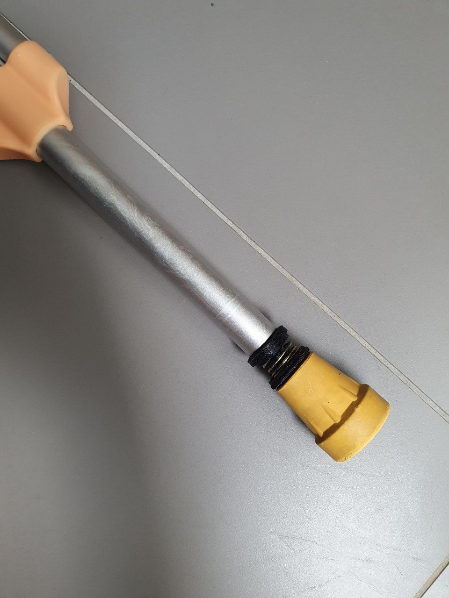

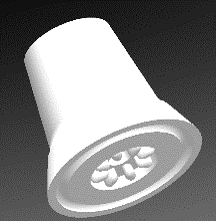

Our team have develop an attachment that incoporate additional normal force to counteract slipping. Using a balljoint, the tip will always have a maximum contact area possible with the surface,

which increases the frictional force. We have also design it to fit most crutches, so one does not have to purchase it but just the attachment. We have used 3D printing

to get the prototype out, as well as the use of Solidworks to model and simulate the loading experience by the attachment.

Future Improvements:

We aim to improve the crutches by exploring different texture and structure design of the rubber tip to further improve the frictional force.

We are also considering changing the material to stronger material, such as ABS or Aluminium.

Materials: PLA

Skills Involved: Solidwork, 3D Printing(FDM)

Photos/Videos: